- 1 Understanding TPU Layflat Hose – Structure and Material Advantages

- 2 Key Applications in Mining Dewatering

- 3 Key Applications in Agricultural Irrigation

- 4 Procurement Tips: How to Choose the Right TPU Layflat Hose

- 4.1 Specification checklist (diameter, wall thickness, pressure rating, length)

- 4.2 Matching the application: large‑diameter vs high‑pressure: "TPU layflat hose abrasion resistant large diameter" & "TPU layflat hose high pressure water transfer" considerations

- 4.3 Supplier and quality assurance: inspecting bonding, reinforcement, UV/chemical resistance

- 5 Maintenance and Lifecycle Considerations

- 6 Why Choose Taizhou Jun'an Fire Technology Co., Ltd. for Your TPU Layflat Hose Needs

- 7 Conclusion

- 8 FAQ

In today's demanding industrial and agricultural environments, selecting the right hose for high‑volume fluid transfer is critical. This guide focuses on how to procure a TPU Layflat Hose effectively, particularly when used for mining dewatering and agricultural irrigation applications. With the right specifications and supplier, you can achieve long service life, reduced downtime, and better overall performance.

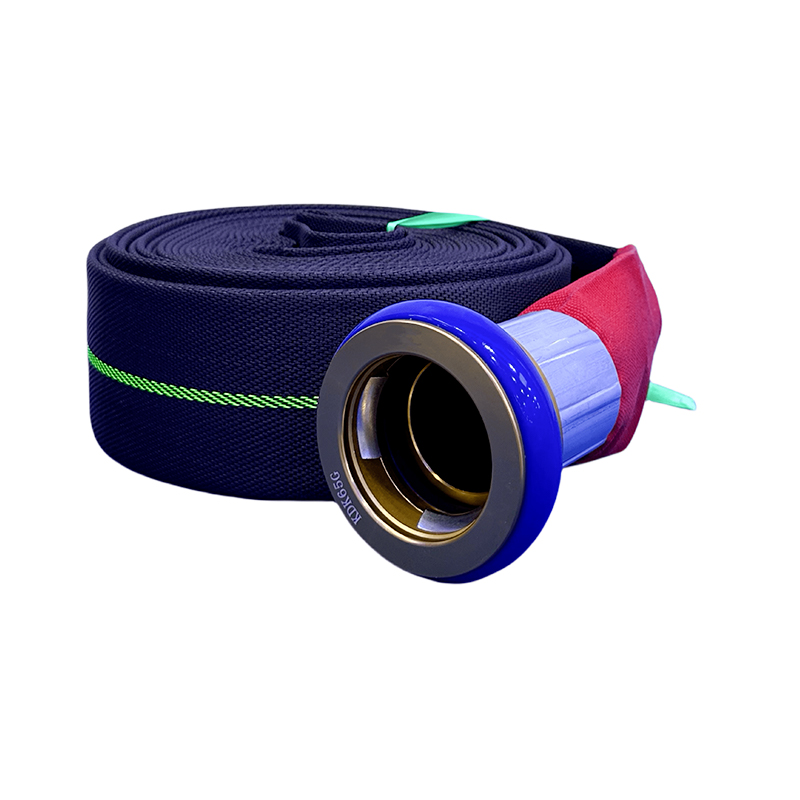

TPU Layflat Hose - Heavy Duty, Lightweight, Durable Water Hose for Irrigation

Understanding TPU Layflat Hose – Structure and Material Advantages

Construction of TPU Layflat Hose

- Inner tube and outer cover are typically made of thermoplastic polyurethane (TPU). :contentReference[oaicite:0]

- Reinforcement is commonly circular‑woven high‑tenacity polyester filament yarn.

- Manufacturing method often uses "extrusion through‑the‑weave" so that the TPU matrix encapsulates the woven reinforcement tightly.

Material benefits compared with PVC or rubber hoses

When comparing hose materials, TPU brings several standout advantages over traditional PVC or rubber for layflat applications.

Comparison table: TPU vs PVC vs Rubber

| Material | Key Advantages | Typical Weaknesses |

|---|---|---|

| TPU | High abrasion resistance, chemical/UV resistance, foldable flat, long length capabilities | Higher unit cost |

| PVC | Lower cost, good for standard water transfer | Less abrasion/chemical resistance, shorter life span |

| Rubber | Good wear resistance, flexible | Heavier, less foldable, may degrade faster under UV/chemicals |

Key Applications in Mining Dewatering

Role of TPU Layflat Hose in mining water removal

In mining operations, excess water and slurry removal is a major challenge. A properly engineered TPU Layflat Hose offers flexibility, abrasion resistance and long‑distance transfer ability, making it well‑suited for mine dewatering systems.

Long‑distance and heavy‑duty transfer: why the "TPU layflat hose mining dewatering" matters

- Large volumes over long distances require minimal joins and consistent diameter.

- Abrasion from slurry and minerals demands high resistant cover — TPU excels in this.

Key Applications in Agricultural Irrigation

Supplying large volumes of water and fertilizer: "TPU layflat hose agricultural irrigation supply" focus

Agriculture demands high‑volume water delivery across large fields, often in remote locations. A TPU Layflat Hose lets you deploy long runs, fold for storage, and handle variable terrain.

Benefits of abrasion and chemical resistance in agriculture: "TPU layflat hose chemical resistant applications"

- Fertilizer and manure delivery systems expose hoses to chemicals and abrasive content; TPU is resistant to acid/alkali, abrasion and UV.

- Less downtime means improved operational efficiency in irrigation cycles.

Procurement Tips: How to Choose the Right TPU Layflat Hose

Specification checklist (diameter, wall thickness, pressure rating, length)

- Nominal internal diameter (ID) must match flow requirements.

- Wall thickness influences burst/working pressure – check manufacturer spec.

- Working pressure vs burst pressure – ensure adequate safety margin.

- Length requirements – longer continuous layflat reduces couplings/leak points.

- Reinforcement type and bonding method – "extrusion through‑weave" preferred.

Matching the application: large‑diameter vs high‑pressure: "TPU layflat hose abrasion resistant large diameter" & "TPU layflat hose high pressure water transfer" considerations

- For long‑distance low/medium pressure water transfer (e.g., irrigation), large diameter layflat hose with moderate pressure rating is adequate.

- For mining dewatering or heavy duty transfer including slurry, you may need smaller diameter but higher pressure rating and extra abrasion resistant cover.

- Always evaluate terrain, fluid type (clean water vs slurry vs chemicals), exposure to UV/abrasion, and required flexibility.

Supplier and quality assurance: inspecting bonding, reinforcement, UV/chemical resistance

Your supplier should provide full specification data, material test reports (abrasion resistance, hydrolysis, chemical resistance) and confirm production method. For example, inspection of cover/lining bonding prevents delamination in harsh environments.

Maintenance and Lifecycle Considerations

Routine inspections and deployment best practice

- Before first use, inspect for manufacturing damage, coupling fitment, correct length run.

- Deploy hose fully flat, avoid twists or kinks — this reduces internal wear.

- After use, drain water, roll flat, store away from direct UV/chemicals to prolong life.

Comparison of lifespan and cost‑effectiveness

Even though initial cost of TPU layflat hose may be higher than PVC, its longer service life, lower downtime and better performance often result in lower total cost of ownership.

Table: Operating cost comparison TPU vs PVC vs Rubber

| Material | Estimated Life Span | Maintenance Frequency | Relative Cost of Ownership |

|---|---|---|---|

| TPU | High | Low | Lowest long‑term |

| PVC | Moderate | Moderate | Moderate |

| Rubber | Moderate | Higher (due to weight/handling) | Higher |

Why Choose Taizhou Jun'an Fire Technology Co., Ltd. for Your TPU Layflat Hose Needs

Located adjacent to the world's largest trading port (Shanghai), Taizhou Jun'an Fire Technology Co., Ltd. specialises in production of hoses (including rubber/PVC/PU lined), fire‑fighting equipment and emergency rescue equipment. The company has modern advanced production equipment, experienced professional management personnel and a senior technical design team. In addition to fire‑fighting hoses, Taizhou Jun'an also offers agricultural hoses and customises OEM/ODM services. With reasonable pricing and high‑quality products, the company has earned customer trust and established long‑term relationships. The company is committed to delivering first‑class equipment and high‑quality after‑sales service to domestic and foreign customers. If you are interested in hose supply, contact the company directly.

Conclusion

Choosing the right TPU Layflat Hose means understanding your application (whether mining dewatering or agricultural irrigation), verifying material and construction quality, matching specifications (diameter, pressure, length) and selecting a reliable supplier. With the proper procurement and maintenance strategy, a TPU layflat hose delivers outstanding performance, durability and total cost savings.

FAQ

- Q1: What is the difference between TPU layflat hose and standard PVC layflat hose?

- A1: The TPU version uses thermoplastic polyurethane for cover and lining plus woven polyester reinforcement; compared with PVC it offers much better abrasion and chemical resistance, longer service life and higher flexibility in rugged environments.

- Q2: Can TPU layflat hose be used for both mining dewatering and agricultural irrigation?

- A2: Yes — it is versatile and suitable for heavy‑duty mining dewatering (excess water, slurry) and for agricultural irrigation (large‑volume water/fertiliser delivery) thanks to its durability and flow capacity.

- Q3: What key specifications should I check when procuring a TPU layflat hose?

- A3: You should check the internal diameter, wall thickness, working and burst pressure ratings, reinforcement construction, total length, coupling compatibility, and material resistance (abrasion, UV, chemicals).

- Q4: How does the cost of TPU layflat hose compare with PVC or rubber hoses?

- A4: While upfront cost may be higher, TPU offers longer lifespan, lower maintenance and fewer replacements, so the total cost of ownership is often lower compared to PVC or rubber in challenging environments.

- Q5: How should I store and maintain a TPU layflat hose to maximise lifespan?

- A5: After use, fully drain the hose, roll it flat or coil it without kinks, store away from direct sunlight/UV if possible, inspect for damage before next use, and avoid dragging the hose over sharp edges or rough surfaces.

en

en

عربى

عربى